Metal Forming Tools & Nitriding

In metal forming tools, the enhancement of properties such as hardness, coefficient of friction, and high stress contact fatigue resistance is of paramount importance for improving productivity and extending tool life.

In applications where the high Hertzian contact stresses are involved in metal forming operations, hardness of the nitrided layer, as well as hardness of the tool underneath it, must be sufficient to resist those conditions. Tools made of M-2 and other similar steels meet those requirements and are treated at Advanced Heat Treat Corp. on a daily basis.

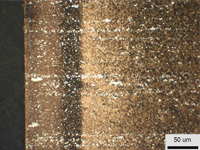

It is essential to make sure that the nitrided layer having such high hardness does not have any network of carbonitrides or uncontrolled white layer thickness. As previously explained, not having proper structure may result in a premature failure of the tool. Microstructure of the layer in M-2 steel tuned up for forming applications is shown in the following figure.

M-2 Tool Steel After UltraGlow Ion Nitriding

Nital etched. Note a barely visible 1 μm (0.00004") thick compound zone on left and diffusion zone underneath.

Have Questions about Metal Forming Tools and/or Nitriding?

CONTACT US